A spring is an elastic device that stores potential energy while at rest, and applies a resistant force when compressed or stretched. Springs are a necessary component in many devices, machines, and systems. Springs are used to store and absorb energy and maintain force or tension in the applications for which they are designed. Read More…

Coiling Technologies, Inc. has the experience and expertise to design and engineer the custom springs to meet your specific requirements. We are a leading manufacturer of high-tech, specialized springs and we are committed to providing quality products with fast lead times. Our automated process allows us to produce the reliable springs you need.

At Stalder Spring Works, we specialize in designing and manufacturing high-quality springs tailored to meet the diverse needs of our customers. With decades of experience, we have built a reputation for precision, durability, and reliability in every spring we produce. Our expertise covers a wide range of industries, ensuring that whether our customers require compression, extension, torsion, or...

At Sterling Springs LLC, we specialize in manufacturing a wide variety of high-quality springs for various industries and applications. Our product line includes compression springs, coil springs, torsion springs, extension springs, and industrial springs. We take pride in our capabilities to produce springs in a wide range of sizes and shapes, from tiny springs for delicate medical devices to...

We offer years of combined experience and also provide production control, purchasing, and sales. We encourage creativity and empower both employees and customers. Our one-of-a-kind company provides many benefits for all our springs customers.

At C&F Wire Products, we dedicate ourselves to the precision design and manufacturing of springs that serve a wide range of industries and applications. With decades of experience, we have built our reputation on consistency, quality, and the ability to deliver solutions that meet the unique needs of our customers.

At Master Spring & Wire Form, we take pride in being a trusted manufacturer of precision springs and custom wire forms. We specialize in producing high-quality compression, extension, and torsion springs that serve a wide range of industries, from automotive and medical to electronics and industrial equipment.

Action Spring has the experience and the expertise to manufacture dependable springs and wire forms for your application. Industries served include aerospace, electronics, recreational, and more. We can manufacture a variety of springs ranging in sizes from .003 to .500., and are able to produce almost any shape and size that a customer may need.

More Spring Manufacturers

Springs are essential mechanical components designed to store and release energy, maintain force, and absorb shock across countless applications. As a cornerstone of both modern and historical engineering, springs play a vital role in industries ranging from automotive and aerospace to electronics, medical devices, and industrial machinery. Whether you are researching spring manufacturers, evaluating spring types for specific use cases, or seeking to optimize product performance, understanding spring design, materials, applications, and standards is crucial for making informed purchasing decisions.

What is a Spring? Function and Purpose

A spring functions as a resilient mechanism that stores potential energy in its quiescent state and exerts opposing force when compressed or stretched. In practical terms, this means that springs are used to store and dissipate energy, absorb or cushion shocks, maintain precise force and tension, and return objects to their original positions. Springs maintain crucial force and tension specific to their applications, making them indispensable in devices, machines, and systems across virtually every sector.

Springs are found in everyday items such as circuit breakers, ballpoint pens, paper clips, solenoid valves, writing instruments, medical devices, electronic lock systems, precision MEMS (Micro-Electro-Mechanical Systems) components, and electronics. In industrial and architectural settings, springs provide seismic protection and vibration isolation for buildings and structures, ensuring safety and longevity.

Technically, springs are elastic objects that store mechanical energy. In the manufacturing world, they are often categorized as coil springs (or helical springs), but the term encompasses a variety of spring types, including compression springs, torsion springs, extension springs, leaf springs, and more.

Key Industries and Applications for Springs

Springs are integral to a vast array of industries and applications, including:

- Automotive and Transportation: Suspension systems, clutches, brakes, engine valves, seat mechanisms, and door handles.

- Medical and Healthcare: Surgical instruments, syringes, inhalers, prosthetics, and diagnostic equipment.

- Consumer Electronics: Keyboards, battery contacts, switches, and connectors.

- Industrial Equipment: Vibration isolators, actuators, stamping presses, and assembly line tools.

- Architecture and Construction: Seismic isolators, elevator counterweights, and structural supports.

- Food and Beverage: Processing equipment, packaging machinery, and dispensing mechanisms.

- Security and Access Control: Electronic locks, latches, and safety mechanisms.

- Nanotechnology and MEMS: Micro-scale springs for sensors, actuators, and precision devices.

Are you searching for a spring solution tailored to your industry or specific application? Explore our spring manufacturer directory to find the right partner.

The History of Springs

The early history of springs remains shrouded in mystery, with scant recorded information. Our insights into their origins largely stem from unearthed artifacts. For example, during the Bronze Age, humans crafted one of the earliest spring-based tools: the tweezer. These implements featured two metal strips with a brazed plate between them. Other innovations from that era included pincer pliers and simple tongs, all leveraging primitive spring mechanics.

Moving into the Iron Age, King Tutankhamun utilized leaf springs to enhance the performance and longevity of his chariots, an early example of springs being used in transportation. By the 1700s, the French had integrated leaf springs into their carriages, improving ride comfort and durability.

In 1493, Leonardo da Vinci pioneered the use of a hammer spring in firearms, enabling single-handed shooting. His ingenuity marked a milestone in spring technology. Nearly two centuries later, British physicist Robert Hooke formulated Hooke’s Law in 1680, stating that “the amount of force (F) required to extend or compress a spring by some distance (X) is linearly proportional to the distance, where the constant (k) represents its stiffness.” The official formula for Hooke’s Law is: F=kX. This fundamental law underpins the engineering and design of springs today.

The evolution continued in 1763 when R. Tradwell invented the coiled spring, a revolutionary advancement over the high-maintenance leaf springs of the time. This new design required less upkeep and minimized squeaking, paving the way for modern suspension and shock absorption technologies.

During the Industrial Revolution’s peak in 1857, the steel coil spring received a U.S. patent for its application in chair seats. Then, in 1871, German inventor Heinrich Westphal introduced the innerspring mattress, though he tragically did not reap financial rewards from his invention.

Fast forward to 1943, when naval engineer Richard James stumbled upon the idea for the Slinky, a coil spring initially designed to steady ship instruments. Its unexpected “walking” movement inspired its name, coined by Richard’s wife, Betty, due to its smooth, graceful motion.

Since those early innovations, advancements in metalworking, heat treatment, and spring design have propelled spring manufacturing forward. Today, springs come in myriad shapes and sizes, offering greater load resistance, fatigue life, and durability than ever before.

Spring Design: Materials, Production, and Customization

Materials

Spring manufacturers utilize a diverse array of materials for their products, including:

- Tempered steel and spring steel – Favored for their elastic properties and high yield strength, making them ideal for load-bearing applications and dynamic environments.

- Cold spring steel and music wire – Chosen for consistent strength, cost-effectiveness, and ease of forming, especially in small compression or extension springs.

- Stainless steel – Widely used in medical, pharmaceutical, and food processing industries due to its corrosion resistance and sterilizability.

- Magnet wire and hastelloy – Utilized in specialized electrical and high-temperature applications, offering unique magnetic and chemical properties.

- Molybdenum and titanium – Selected for high-strength, lightweight, and high-temperature environments such as aerospace, defense, and advanced manufacturing.

- Copper and bronze – Provide excellent conductivity and corrosion resistance, often used in electrical contacts and marine applications.

- Thermoplastics – Increasingly popular in environments requiring corrosion resistance, electrical insulation, and noise reduction. Common in automotive interiors, consumer products, and sensitive electronics.

- Braided wire materials – Used for springs that must withstand sudden, heavy loads or require enhanced flexibility and fatigue resistance.

Production Methods

Springs are manufactured using either cold rolling or hot rolling processes. Cold rolling accommodates wires up to 5/8” in diameter, resulting in precision springs for lighter applications. Hot rolling allows for the fabrication of springs from straight bars of steel up to 6” in diameter, ideal for heavy-duty shock absorption in industrial settings.

Advances in micro-manufacturing enable the production of lightweight micro wires, as fine as .01” or .002”, for specialized miniature springs used in electronics, medical devices, and high-tech applications. Manufacturers also shape stronger springs using flat and square wires, in addition to traditional round wires and tubular stock. Industrial springs are typically made from thicker wires for high-load environments, while smaller springs employ flexible, thin wires that can be nearly invisible to the naked eye.

The most common production method involves winding wire around a metal blank, which can be adapted to create electrical coils using conductive wire. Precision is paramount; therefore, CNC programmable machines are used to achieve tight tolerances and intricate designs. The choice of metal and its properties significantly influence the compressibility, fatigue life, and performance of the final product.

Customization and Engineering Considerations

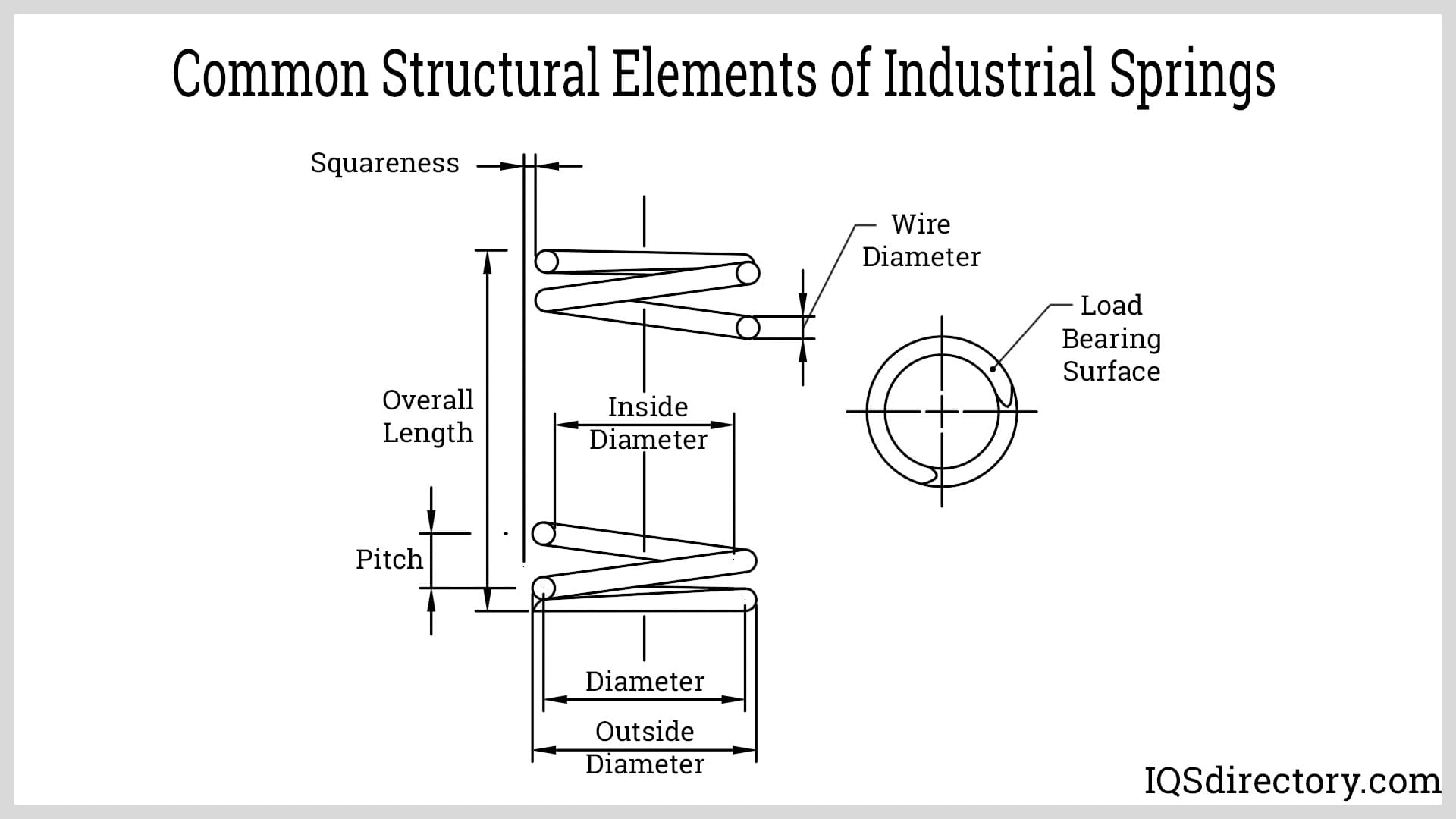

When designing and customizing springs, manufacturers meticulously consider:

- Spring rate and stiffness

- Physical dimensions, including wire diameter, coil diameter, and free length

- Anticipated load requirements and operating cycles

- Application-specific factors such as temperature, corrosion, and dynamic stress

- Number of active coils and material selection

- Surface treatments, coatings, and hardening processes for enhanced performance

- Color coding or identification for easy recognition in complex assemblies

These factors dictate the spring’s ability to store and release energy, its load capacity, fatigue resistance, and suitability for the intended environment. Tailoring springs through advanced surface treatments—such as plating, passivation, shot peening, or powder coating—ensures optimal performance, especially in corrosive or high-wear conditions.

Looking to design a custom spring for your project? Contact expert spring manufacturers to discuss your application, requirements, and optimal material choices.

Comprehensive Guide to Spring Types

Springs come in a variety of styles, each engineered for unique functions. Understanding the different types of springs is crucial for selecting the right component for your application.

Coil Spring (Helical Spring)

Coil springs, also known as helical springs, are produced by winding spring wire around a cylinder to form a helix. These springs are typically manufactured from steel or stainless steel, offering resilience and adaptability for a wide range of uses. Major subtypes include:

- Compression springs

- Extension springs

- Torsion springs

Compression Spring

Compression springs are designed to cushion downward forces and absorb shock. Common examples include bed springs, vehicle suspension systems, industrial machinery, and vibration isolators. They resist external pressure, with stiffness influenced by factors such as wire material, coil diameter, and number of coils. Compression springs are ideal for applications that require energy absorption and load support.

Extension Spring

Extension springs elongate to resist pulling forces, returning to their original length when the force is removed. Commonly found in screen doors, medical equipment, garage doors, and mechanical linkages, extension springs are specified by free length, coil diameter, wire gauge, and end fittings such as hooks or loops.

Torsion Spring

Torsion springs exert torque along a circular arc, resisting rotational or twisting forces. These springs are vital in applications ranging from mousetraps and clothespins to vehicle trunk lids, garage doors, and precision electronics. Torsion spring material and configuration are chosen based on required torque, operating environment, and cycle life.

The torsion spring is a variant of the spiral spring, providing resistance to rotating external forces. The ends of this spring are usually attached to other components and will resist when external forces rotate around the center of the spring. Consult with an expert to select the appropriate material and design for your industry, whether automotive, electronics, or industrial machinery.

Flat Spring

Unlike coiled springs, flat springs are made from flattened strips of metal or plastic, curved or stamped to absorb shocks and resist deformation. Leaf springs, a type of flat spring, are prevalent in heavy vehicles like trucks and trains, prized for their durability and load-bearing capacity. Flat springs are also common in electrical contacts, relays, and precision mechanical devices.

Constant Force Spring

Combining flat and coil spring principles, constant force springs consist of coiled sheet metal that provides a consistent energy output throughout its extension and retraction. They are vital in applications requiring a steady force, including tape measures, cable retractors, window counterbalances, and electric motors.

Conical Spring

Conical springs, or tapered springs, have a wide base and a narrow top, maintaining a nearly constant spring rate under compression. Their geometry offers stability and minimal deflection, making them suitable for electrical contacts, push buttons, and space-constrained assemblies. Materials like copper or stainless steel are commonly used.

Gas Spring

Gas springs use compressed gas sealed within a cylinder to store and release energy, operating via a piston mechanism. They withstand parallel external forces and are widely used in automotive applications (such as liftgates, hoods, and seats), aerospace, medical devices (exam tables, hospital beds), furniture (office chairs, adjustable beds), and industrial machinery, offering smooth motion and reliable support.

Advantages of Using Springs

Why choose springs over alternative mechanisms? Springs offer several distinct advantages:

- Energy Storage and Release: Springs efficiently store mechanical energy upon deformation and release it when needed, making them indispensable for shock absorption, suspension, and energy regulation.

- Durability Under Repetitive Stress: Unlike elastomers or rubber, springs maintain their properties and performance over millions of cycles, offering superior fatigue life.

- Flexibility and Forgiveness: Springs accommodate varying loads and absorb impacts, reducing damage and wear in mechanical systems compared to rigid linkages.

- Customizability: By adjusting materials, wire diameters, and coil configurations, springs can be engineered for precise stiffness, damping, and load-bearing capacities.

- Simplicity and Cost-Effectiveness: Springs are often less complex than hydraulic or pneumatic systems, requiring less maintenance and lower upfront costs.

- Versatility: Springs are used in applications ranging from microelectromechanical systems (MEMS) to heavy-duty industrial machinery, supporting diverse use cases.

Looking for solutions that maximize shock absorption, load support, and reliability? Springs are the proven choice for engineers, product designers, and OEMs worldwide.

Spring Accessories and Hardware

Accessories and hardware play pivotal roles in enhancing the performance and versatility of springs across diverse applications. Here’s a breakdown of these essential components and their uses:

- Spring Mounts/Seats: Securely position springs within mechanical systems, ensuring stable alignment, even load distribution, and reduced stress concentrations. Critical for automotive suspensions and industrial assemblies.

- Coil Spring Isolators: Also known as shock mounts, these components isolate springs from surrounding structures, minimizing vibration and noise transmission. Frequently used in vehicle suspensions and industrial machinery.

- Felt Inserts: Placed between coils to reduce friction and dampen noise during compression and extension, prolonging spring life by preventing metal-on-metal contact.

- Ball Studs: Enable pivoting connections and angular movement between springs and components, essential in automotive suspensions and dynamic assemblies.

- End Fittings (Hooks, Loops): Attach to spring ends for seamless integration into surrounding structures. Chosen based on load requirements and application demands.

Choosing the right spring accessories depends on:

- Intended use and load requirements

- Environmental conditions (temperature, corrosion, outdoor exposure)

- Desired performance characteristics (vibration damping, noise reduction)

- Installation and maintenance needs

Consulting with experienced engineers and rigorous testing under real-world conditions are key to selecting the right accessories for optimal functionality and longevity. Have questions about integrating springs or selecting the right hardware? Contact our experts or explore top-rated spring suppliers.

Proper Care, Maintenance, and Storage of Springs

Ensuring the longevity and optimal performance of springs requires diligent care and maintenance. Here are best practices for maximizing your spring investment:

- Regular Inspections: Identify early signs of wear, deformation, or corrosion to allow timely intervention and prevent failures.

- Appropriate Lubrication: Reduce friction between coils, minimize wear, and ensure smooth operation, especially in dynamic or high-cycle applications.

- Avoid Overloading: Prevent excessive forces that can cause permanent deformation or early spring failure by adhering to specified load limits.

- Corrosion Protection: Use appropriate coatings or select inherently corrosion-resistant materials (e.g., stainless steel, plastic) for harsh or outdoor environments.

- Temperature Management: Recognize that extreme temperatures can affect spring properties. Select materials suited for the intended temperature range.

- Proper Installation: Ensure correct alignment and mounting to avoid stress concentrations and premature wear.

- Optimal Design: Collaborate with spring engineers to tailor the spring to your specific application, ensuring reliability and efficiency.

- Safe Storage: Store springs in clean, dry environments to prevent contamination, rust, or loss of mechanical properties.

By following these guidelines, users can ensure efficient operation, longer lifespan, and reduced costs due to premature failures or downtime.

Standards for Springs: Ensuring Quality and Safety

Industry and governmental standards are critical for ensuring the safety, performance, and compatibility of springs. Key organizations include:

- SAE (Society of Automotive Engineers): Sets standards for automotive springs, covering suspension, engine, and brake systems to ensure safety and reliability.

- ASTM International: Publishes technical standards for spring materials, manufacturing processes, and testing procedures, ensuring quality across industries.

- ISO (International Organization for Standardization): Develops global standards for spring dimensions, materials, and performance, facilitating international trade and product interoperability.

- AISI (American Iron and Steel Institute): Establishes material standards for iron and steel used in spring manufacturing, ensuring strength and durability.

Compliance with these standards provides clear guidelines for material selection, manufacturing, and testing. Adhering to industry standards ensures springs are safe, reliable, and interchangeable, reducing costs and streamlining supply chains. Non-compliance can result in safety hazards, equipment failures, and legal liabilities, especially in critical industries like automotive and aerospace.

For manufacturers, compliance enhances credibility and marketability; for users, it ensures springs meet specific quality and performance requirements. International standards also facilitate global trade and product compatibility.

Have questions about spring standards or certification? Contact qualified spring suppliers or consult our manufacturer listings to ensure your next project meets all necessary specifications.

How to Select the Right Spring Manufacturer

Springs may appear simple, but their performance is highly dependent on expert manufacturing and precise engineering. To ensure your project succeeds, partner with an experienced, reliable spring manufacturer who understands your application and requirements. Here are the steps to follow:

- Define Your Requirements: Prepare a detailed list of specifications, including application details, projected load, physical dimensions, environmental factors (corrosive, outdoor, sterile), budget, timeline, and delivery needs.

- Shortlist Potential Suppliers: Choose three or four manufacturers with proven expertise in your desired spring type and application. Explore customer reviews, industry certifications, and case studies to gauge their capabilities.

- Engage and Compare: Contact each manufacturer directly. Discuss your requirements in detail, ask for engineering input, and evaluate their responsiveness and willingness to collaborate.

- Evaluate Customer Service and Expertise: Assess which supplier provides the best customer service, technical support, and manufacturing capabilities for your project.

- Make an Informed Decision: Choose the manufacturer that combines engineering expertise, high-quality products, and excellent customer service.

Looking for trusted partners? Browse our curated list of spring manufacturers and connect with industry leaders ready to meet your needs.

Frequently Asked Questions About Springs

- What are the most common types of springs and their uses?

Compression springs for shock absorption, extension springs for tension applications, and torsion springs for rotational force are the most widely used types. Leaf, conical, and gas springs serve specialized roles. - How do I select the right material for my spring?

Consider required load, environment, corrosion resistance, temperature exposure, and fatigue life. Consult with spring design experts for optimal material selection. - What standards should my springs comply with?

Depending on your industry, SAE, ASTM, ISO, and AISI standards may apply. Always verify compliance to ensure safety and reliability. - Can I order custom springs for unique applications?

Absolutely. Most spring manufacturers offer custom engineering and prototyping services for specialized designs, materials, and coatings. - How do I maintain springs for maximum performance?

Perform regular inspections, apply lubrication, avoid overloading, and use corrosion protection as needed.

Still have questions? Contact our spring experts or request a quote for your next project.

Conclusion: Springs as the Backbone of Mechanical Innovation

Springs are the unsung heroes of modern engineering, enabling motion, energy management, and precision across industries. By understanding spring types, materials, manufacturing processes, standards, and maintenance best practices, you can make informed decisions that improve product performance and reliability. Whether you are designing a new product, sourcing for industrial applications, or seeking to optimize existing systems, partnering with a knowledgeable spring manufacturer is the key to success.

Explore our resources and connect with industry-leading spring manufacturers to get started on your next project today.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services