They measure between 0.0036 and 0.187 inches thick, and smaller springs are always in development. Springs are found in many different industries, and small springs are no exception, although they are most commonly found within electronic systems. Read More…

Coiling Technologies, Inc. has the experience and expertise to design and engineer the custom springs to meet your specific requirements. We are a leading manufacturer of high-tech, specialized springs and we are committed to providing quality products with fast lead times. Our automated process allows us to produce the reliable springs you need.

At Stalder Spring Works, we specialize in designing and manufacturing high-quality springs tailored to meet the diverse needs of our customers. With decades of experience, we have built a reputation for precision, durability, and reliability in every spring we produce. Our expertise covers a wide range of industries, ensuring that whether our customers require compression, extension, torsion, or...

At Sterling Springs LLC, we specialize in manufacturing a wide variety of high-quality springs for various industries and applications. Our product line includes compression springs, coil springs, torsion springs, extension springs, and industrial springs. We take pride in our capabilities to produce springs in a wide range of sizes and shapes, from tiny springs for delicate medical devices to...

We offer years of combined experience and also provide production control, purchasing, and sales. We encourage creativity and empower both employees and customers. Our one-of-a-kind company provides many benefits for all our springs customers.

At C&F Wire Products, we dedicate ourselves to the precision design and manufacturing of springs that serve a wide range of industries and applications. With decades of experience, we have built our reputation on consistency, quality, and the ability to deliver solutions that meet the unique needs of our customers.

At Master Spring & Wire Form, we take pride in being a trusted manufacturer of precision springs and custom wire forms. We specialize in producing high-quality compression, extension, and torsion springs that serve a wide range of industries, from automotive and medical to electronics and industrial equipment.

Action Spring has the experience and the expertise to manufacture dependable springs and wire forms for your application. Industries served include aerospace, electronics, recreational, and more. We can manufacture a variety of springs ranging in sizes from .003 to .500., and are able to produce almost any shape and size that a customer may need.

More Small Spring Manufacturers

Comprehensive Guide to Small Springs: Types, Applications, and Manufacturing Insights

Small springs play a vital role in modern technology and manufacturing, serving as essential components in a wide array of industries and products. From the intricate mechanisms inside electronic devices to the highly specialized components used in medical equipment, small springs are designed to deliver precise force, flexibility, and resilience. As the demand for miniaturization and high-performance materials increases, understanding the types, applications, and production methods of small springs is critical for engineers, designers, procurement specialists, and manufacturers alike.

What Are Small Springs?

Small springs, sometimes called miniature springs or micro springs, are mechanical devices engineered to store and release energy, mitigate shock, or maintain a force between contacting surfaces. Despite their diminutive size, their engineering complexity is significant, and they are manufactured to exacting tolerances using advanced processes.

These springs can be as small as fractions of a millimeter in diameter, with some micro springs fabricated under a microscope in clean room facilities to meet the demanding requirements of industries like electronics and medical device manufacturing. Their size does not diminish their mechanical importance; in fact, their compactness often enhances the performance and reliability of the products they are integrated into.

Types of Small Springs

Small springs are classified according to their function and design. The most common types include:

- Compression Springs: These springs compress under load and return to their original shape when the load is released. They are used for absorbing shock or maintaining a force between two components.

- Torsion Springs: Designed to work by twisting, these springs exert a torque or rotary force. Torsion springs are common in hinges and levers.

- Extension (Tension) Springs: These springs are stretched to create a force and return to their original form when released. They are frequently used in applications requiring a pulling force.

Additionally, specialty variants like flat wire springs, constant force springs, and custom micro springs are used for unique or demanding applications.

Materials Used in Small Spring Manufacturing

The choice of material is critical for ensuring the performance, durability, and corrosion resistance of miniature springs. The most widely used materials include:

- Austenitic Stainless Steels (302, 304, 316): Offer excellent corrosion resistance and are suitable for medical, marine, and electronic applications.

- Music Wire: Known for its high tensile strength and fatigue resistance, making it ideal for dynamic or high-stress environments.

- Phosphor Bronze and Beryllium Copper: Provide good electrical conductivity, making them suitable for electronic connectors and switchgear.

- Pre-Plated Zinc: Used where extra corrosion protection is needed.

- Specialty Alloys (e.g., Hastelloy): Employed in extreme environments where standard materials may not suffice.

Wire for small springs is typically formed using cold rolling or cold extrusion processes, which enhance mechanical strength compared to hot rolling. The choice of wire diameter and material grade is determined by the application’s load, required deflection, and environmental conditions.

Where Are Small Springs Used? Key Applications and Industries

Miniature springs are indispensable across a wide range of sectors. Their adaptability and precision make them the go-to solution for engineers and product designers facing size and performance constraints.

Electronics and Microelectronics

Electronic springs are fabricated under strict conditions, often in cleanroom facilities using microscopes to meet the miniaturization demands of modern devices. They are commonly found in:

- Cell phones and smart devices

- Laptops and desktop computers

- Electronic scales and measurement instruments

- Microelectromechanical systems (MEMS)

- Wearable electronics

- Camera modules and lens assemblies

In electronic assemblies, small springs provide electrical contact, maintain pressure on connectors, and ensure reliable tactile feedback in user interfaces such as keyboards and touchpads.

Medical Devices and Life Sciences

The medical industry relies on precision micro springs for devices that demand reliability and biocompatibility. Applications include:

- Hearing aids

- Catheters and guidewires

- Endoscopes

- Surgical instruments

- Implantable devices

- Micro-pumps and drug delivery systems

These springs must meet stringent regulatory requirements and often require specialized materials and surface finishes for safe patient contact and optimal function.

Industrial and Commercial Equipment

Small springs play a crucial role in:

- Appliances such as commercial dryers

- Hardware assemblies

- Firearms and safety mechanisms

- Circuit breakers and electrical panels

- Lighting fixtures

- Pools, spas, and water treatment

- Toys and hobby products

- Automotive components

- Watches and timepieces

- Locks and security devices

- Fishing equipment

- Writing instruments (pens, mechanical pencils)

In these diverse applications, miniature springs are critical for actuation, positioning, shock absorption, and maintaining consistent performance under repeated use.

Emerging Technologies and Custom Applications

As technology advances, the demand for custom micro springs in fields such as aerospace, robotics, and nanotechnology continues to grow. These applications often require:

- Ultra-precise tolerances

- Exotic materials

- Specialized coatings and finishes

- Integration with MEMS and NEMS (Nanoelectromechanical systems)

Are you searching for a miniature spring manufacturer that can deliver custom solutions for your next project? Learn more about micro spring design and custom fabrication.

How Are Small Springs Manufactured?

Manufacturing small springs requires advanced machinery and precise control. While larger springs are typically formed from annealed metal and then hardened, miniature springs are wound from pre-hardened wire to ensure material integrity throughout the fabrication process.

Key steps in manufacturing include:

- Wire preparation: Selecting and preparing the correct wire diameter and material type

- Coiling: Using micro-coilers—sophisticated CNC (Computer Numerical Control) machines—to wind the wire into the desired spring configuration

- Heat treatment: Stress-relieving the spring to enhance fatigue life and maintain dimensional stability

- Finishing processes: Including grinding, polishing, passivation, and plating to achieve the required surface properties and corrosion resistance

- Quality control: Rigorous inspection and testing to verify spring performance, dimensions, and compliance with industry standards

State-of-the-art CNC machinery allows for high-volume, automated production with minimal variability, which is essential for industries that require consistent, high-quality miniature springs. Manufacturers who specialize in small springs often handle the entire process from design to finishing in-house, ensuring tight quality control and fast turnaround times.

Benefits of Using Small Springs in Product Design

Engineers and product designers choose miniature springs for a variety of compelling reasons:

- Precise Force Control: Ideal for applications where accuracy and repeatability are critical

- Space-Saving Design: Enables more compact and lightweight products

- Enhanced Product Performance: Reduces wear, improves tactile feedback, and increases reliability

- Wide Material and Finish Options: Adaptable to harsh environments, cleanrooms, and biocompatible settings

- Customization: Springs can be engineered to meet specific force, deflection, and dimensional requirements

- Cost-Effective Manufacturing: Advanced automation and CNC technology lower per-part costs in high volumes

Need to Select the Right Small Spring for Your Application?

When researching which miniature spring best fits your needs, consider these key decision factors:

- Required force and load capacity

- Available installation space

- Environmental conditions (temperature, humidity, corrosive agents)

- Material and surface finish requirements

- Compliance with regulatory or industry standards

- Expected lifecycle and fatigue resistance

- Volume and cost constraints

For a more detailed spring selection guide, explore: Spring Design Considerations

Common Buyer Questions About Small Springs

Below are some of the most frequently asked questions from engineers, buyers, and procurement teams seeking miniature spring solutions:

What is the smallest spring size available for custom manufacturing?

Manufacturers can produce springs with wire diameters as small as 0.03 mm (30 microns), depending on the material and application. For very small or specialized needs, contact a spring manufacturer to discuss feasibility and design recommendations.

Can small springs be made from non-magnetic or medical-grade materials?

Yes. Many miniature springs are made from non-magnetic stainless steel or biocompatible alloys to meet medical, aerospace, or sensitive electronic requirements.

How do you ensure the quality and reliability of micro springs?

Leading manufacturers utilize advanced inspection systems, including laser measurement, digital microscopy, and automated force testing. They also follow ISO 9001 and ISO 13485 quality management systems for consistency and traceability.

What is the turnaround time for custom miniature springs?

Lead times vary depending on design complexity, material availability, and order volume. Rapid prototyping is often available, while production runs can be completed in a few weeks. Early engagement with the manufacturer is recommended for complex or high-volume projects.

Looking for design support or a quote?

Connect with a miniature spring design expert to discuss your project specifications, request samples, or obtain pricing information tailored to your application.

How to Specify and Order Small Springs

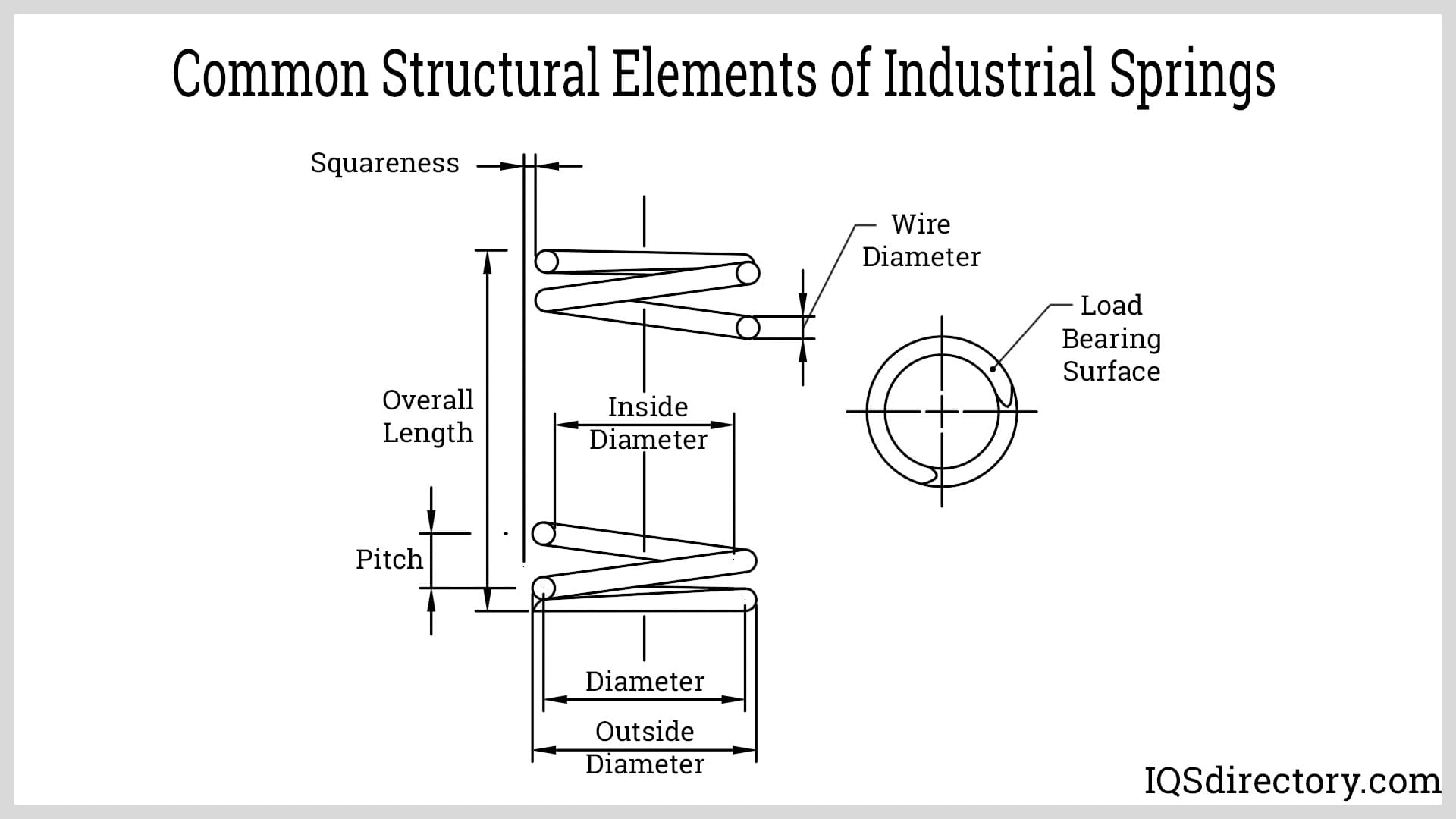

When preparing to order miniature springs, providing detailed specifications ensures accurate manufacturing and optimal performance. Typical information required includes:

- Spring type (compression, extension, torsion, custom)

- Wire material and diameter

- Outer and inner coil diameters

- Free length and solid height

- Number of active coils

- Load at specific deflection

- Surface treatment or plating requirements

- Packaging and cleanliness requirements (especially for medical or electronic applications)

Ready to get started? Request a quote or consult with a spring manufacturing specialist for guidance on your next order.

Industry Trends: The Future of Small Springs

The ongoing trend toward miniaturization in electronics, medical devices, and precision engineering is driving innovation in the field of small spring design and manufacturing. Key developments include:

- Microfabrication techniques: Including additive manufacturing (3D printing) and laser micromachining for even smaller, more complex spring geometries

- Advanced materials: Research into shape-memory alloys, superelastic metals, and nano-engineered surfaces for next-generation performance

- Automation and digital quality control: Increasing production efficiency and product consistency

- Sustainability: Focus on recyclable materials, energy-efficient processes, and environmentally friendly coatings

Curious about how small springs can drive your product innovation? Explore our resources or contact our engineering team for up-to-date technical guidance.

Conclusion: Why Choose a Specialized Small Spring Manufacturer?

Choosing a manufacturer with expertise in miniature spring production ensures access to the latest technology, high-precision processes, and the ability to customize solutions for demanding applications. Whether you require compression springs for consumer electronics, torsion springs for aerospace mechanisms, or micro springs for medical devices, partnering with a dedicated spring specialist streamlines your supply chain and accelerates time to market.

Ready to take the next step in sourcing high-quality small springs? Contact a miniature spring design and manufacturing expert today to discuss your application, request technical drawings, or receive a competitive quote.

For further reading and resources on precision springs, micro spring fabrication, and advanced spring design, visit our Spring Design Resource Center.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services