A compression spring is an open coil helical spring that can resist axial compressive force. Compression springs can be coiled at constant diameters and in various shapes, including convex, concave, and conical. Compression springs can store energy or resist compressive force. Read More…

Coiling Technologies, Inc. has the experience and expertise to design and engineer the custom springs to meet your specific requirements. We are a leading manufacturer of high-tech, specialized springs and we are committed to providing quality products with fast lead times. Our automated process allows us to produce the reliable springs you need.

At Stalder Spring Works, we specialize in designing and manufacturing high-quality springs tailored to meet the diverse needs of our customers. With decades of experience, we have built a reputation for precision, durability, and reliability in every spring we produce. Our expertise covers a wide range of industries, ensuring that whether our customers require compression, extension, torsion, or...

At Sterling Springs LLC, we specialize in manufacturing a wide variety of high-quality springs for various industries and applications. Our product line includes compression springs, coil springs, torsion springs, extension springs, and industrial springs. We take pride in our capabilities to produce springs in a wide range of sizes and shapes, from tiny springs for delicate medical devices to...

We offer years of combined experience and also provide production control, purchasing, and sales. We encourage creativity and empower both employees and customers. Our one-of-a-kind company provides many benefits for all our springs customers.

At M & S Spring Co., Inc., we focus on manufacturing precision wire forms and springs that are built to perform reliably in demanding applications. Our work centers on transforming raw wire into functional components that maintain consistent performance under load, motion, and repeated cycling. By combining experienced craftsmanship with modern forming equipment and disciplined process control,...

At Spring Dynamics, Inc., we take pride in designing and manufacturing springs that deliver exceptional performance across a wide range of applications. Our expertise allows us to create precision-engineered compression, extension, torsion, and custom springs that meet the demanding requirements of industries such as automotive, aerospace, medical, and industrial equipment.

Action Spring has the experience and the expertise to manufacture dependable springs and wire forms for your application. Industries served include aerospace, electronics, recreational, and more. We can manufacture a variety of springs ranging in sizes from .003 to .500., and are able to produce almost any shape and size that a customer may need.

More Compression Spring Manufacturers

Working Principle Of Compression Spring

When a heavy load is given to a compression spring, they keep the weight until it is released. Compression springs always have an axially loaded compressive force. Compression springs are commonly used because they are incredibly effective.

For specific uses, manufacturers can make compression springs in different forms or sizes. They can be mounted on a rod, or inserted in a hole. They can be adapted to many customized services. Additionally, tailored springs can share traits like nonlinear load deflection, incredibly high spatial efficiency, and increased energy storage capacity.

General Parameters Used for Compression Springs

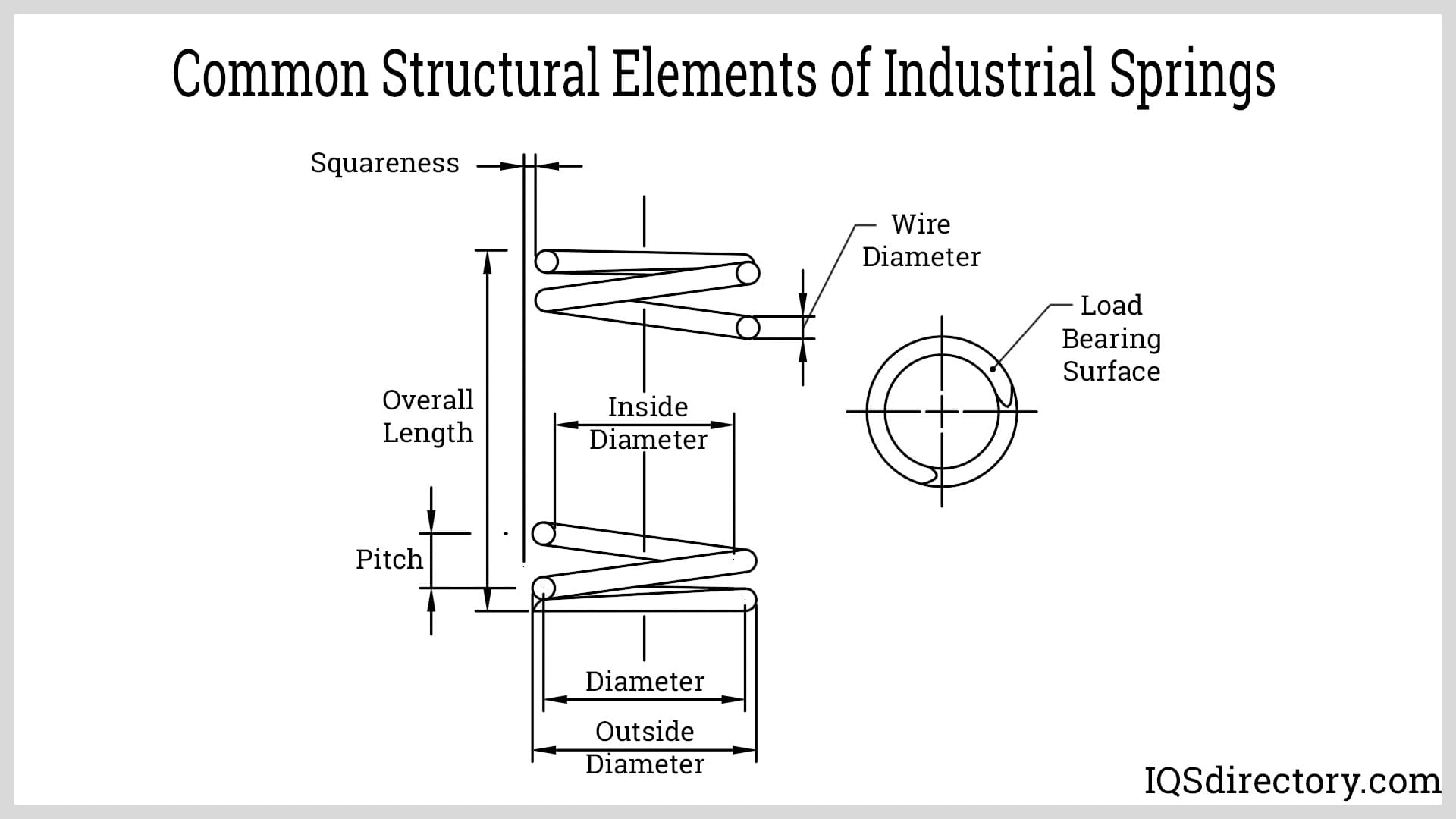

When designing or purchasing compression springs, manufacturers should consider may of the following parameters.

- Rate refers to the unit of measurement is the newton per millimeter rate of change of load.

- Stress: A compression spring experiences stress whenever it is loaded, and the stress value is highest near the wire's surface. The amount of tension determines the spring's lifespan. Less stress is produced in the spring's body when the operational stress range is wider. When the working stress range is limited, higher stress is used.

- Ends of the Spring: End circumstances typically fall into one of four categories. The coils at the end can be closed or opened, and the end can be both grounded and ungrounded.

- External Dimension: This refers to the diameter created by the spring coil's exterior surface.

- The hole dimension is the diameter that the spring is placed into. It can also be referred to as the spring's mating part diameter. To allow for spring expansion when a load is applied, manufacturers should design hole diameters to be larger than the spring's outside diameter.

- Rod diameter refers to the diameter of a rod placed through a spring. The shaft serves as a guide to reduce spring buckling when under compressive strain. The rod's diameter is always intended to be less than the spring's internal diameter. Still, it should be manageable, or the spring's capacity to minimize buckling will be lost.

- Free length is refers to the of the spring as measured when it is not loaded.

- Wire diameter refers to the size of the spring-making raw material. Conventional springs are made using round wires with a specific diameter.

- Solid is the height of a spring when fully loaded.

Types of Compression Springs

Magazine Springs

Magazine springs are rectangular or oval-shaped coils. Firearms, along with other gadgets often use magazine springs.

Conical Springs

The solid height of the compression springs is decreased by using conical springs. They can achieve this because of the telescoping effect that their shape provides. However, conical compression springs do not exert a constant force during compression because they are nonlinear.

Barrel Springs

Barrel springs are used to provide the spring with stability and lower the solid height. Like conical springs, barrel springs are nonlinear.

Torsional Springs

Torsional springs offer suspension against objects and are helpful when dealing with radial force.

Types of Compression Springs-Based On Shape

A conical-shaped compression spring has a decreasing radius near the ends of the springs. They are typically used for battery springs. Hourglass-shaped compression springs have a tapered core, while the outer coils’ diameter is bigger.

A barrel-shaped compression spring is designed narrower at the ends and wider in the middle.

Reduced-end compression springs have a straight center but slightly tapered end coils.

Material Used for Compression Spring

Steel alloys are often used as spring materials. However, manufacturers often use other common alloys like low-carbon, high-carbon, oil-tempered stainless steel, chrome silicon, and chrome vanadium. Springs can occasionally be made from phosphor bronze, titanium, and beryllium copper alloy. Ceramic materials are used to make coiled springs used in high-temperature settings.

Common Compression Spring Applications

Compression springs are incredibly strong and can be created in various sizes. Compression springs are, therefore, perfect for a variety of applications, the majority of which are found in daily life. Examples include pens, pogo sticks, couches, mattresses, locks, button-operated devices or mechanisms, automobile suspension, and various medical devices

Advantages of Compression Springs

Compression springs can be used to stop components from moving, or return components to their proper position after a load is removed. Compression springs deliver steady pressure and stability while being flexible and lightweight.

Disadvantages of Compression Spring

Costly conical springs are expensive and become weaker if kept compressed for a long time. Springs can deteriorate over time, losing both rigidity and shape. If the spring is broken, fixing it is challenging.

Choosing the Right Compression Spring Manufacturer

To make sure you have the most productive outcome when purchasing compression springs from a compression spring manufacturer, it is important to compare at least 5 to 6 companies using our list of compression spring manufacturers. Each compression spring manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each compression spring business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple compression spring companies with the same message.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services